Umhlaba wezimo eziphuthumayo nokuphepha kwezimboni kuncike kakhulu ezintweni ezithembekile, ezisebenza kahle. Enye ingxenye ebalulekile ithuluzi lokuphefumula, isisindisi sempilo sabacimi bomlilo, abaphenduli bokuqala, kanye nabasebenzi abasebenza ezindaweni eziyingozi. Ngokwesiko, lawa mathuluzi ayesebenzisa amasilinda ensimbi ukuze agcine umoya owuphefumulayo. Kodwa-ke, uguquko oluguquguqukayo luyaqhubeka ngokutholwa okukhulayo kwei-carbon fibre cylinders. Lesi sihloko sihlola ukwakheka kanye nentuthuko yobunjiniyela ngemuvai-carbon fibre cylinders kumishini yokuphefumula, egqamisa izinzuzo ezinikezayo uma kuqhathaniswa nozakwabo bensimbi.

Amandla Ahlangabezana Nempumelelo: Ukukhanga Kwesilinganiso Samandla-kuya-Isisindo

Umshayeli oyinhloko wokwamukelai-carbon fibre cylinderImishini yokuphefumula ilele ngendlela ehlukileisilinganiso samandla nesisindo. Amafayibha ekhabhoni, wona ngokwawo aqine ngendlela emangalisayo futhi engasindi, alukwe ngobunono futhi ashunyekwa ku-matrix ye-resin ukuze kwakheke into eyinhlanganisela. Lokhu kubangela isilinda esizidla ngamandla amakhulu kuyilapho ihlala ilula ngokuphawulekayo. Kuzicishamlilo nabanye ochwepheshe abaphethe amathuluzi okuphefumula isikhathi eside, lokhu kuhumushela kunzuzo enkulu.

Ake ucabange ngesicishamlilo silwa nomlilo, sizulazula emaphaseji agcwele intuthu kuyilapho siphethe izinto ezisindayo. Wonke ama-ounce abalulekile. Ukushintsha amasilinda ensimbi ngozakwabo bawo be-carbon fiber elula kunciphisa isisindo sonke semishini yokuphefumula, okuholela kulokhu:

-Ukukhathala okwehlisiwe:Imishini elula ivumela ukukhuthazela okungcono nokuhamba, okubalulekile ekusebenzeni okunwetshiwe.

-Ukusebenziseka Okuthuthukisiwe:Isisindo esilula sithuthukisa ikhono lomuntu ogqokile lokuzulazula ezindaweni ezimpintshana noma ukugibela izitebhisi kalula.

-Ukuphepha Okuthuthukisiwe:Ukukhathala okuncishisiwe kuhumusha ekwenzeni izinqumo okuthuthukisiwe kanye nengozi ephansi yokulimala phakathi nezimo ezibucayi.

Lokhu kunciphisa isisindo kuphinde kuzuzise abasebenzi basezimbonini abathembele kumshini wokuphefumula ukuze bangene esikhaleni esivalekile noma abasebenza ezindaweni eziyingozi. Yonke iphawundi elondoloziwe ihumusha ekukhululekeni okwengeziwe nokuphepha kwezisebenzi okuthuthukisiwe.

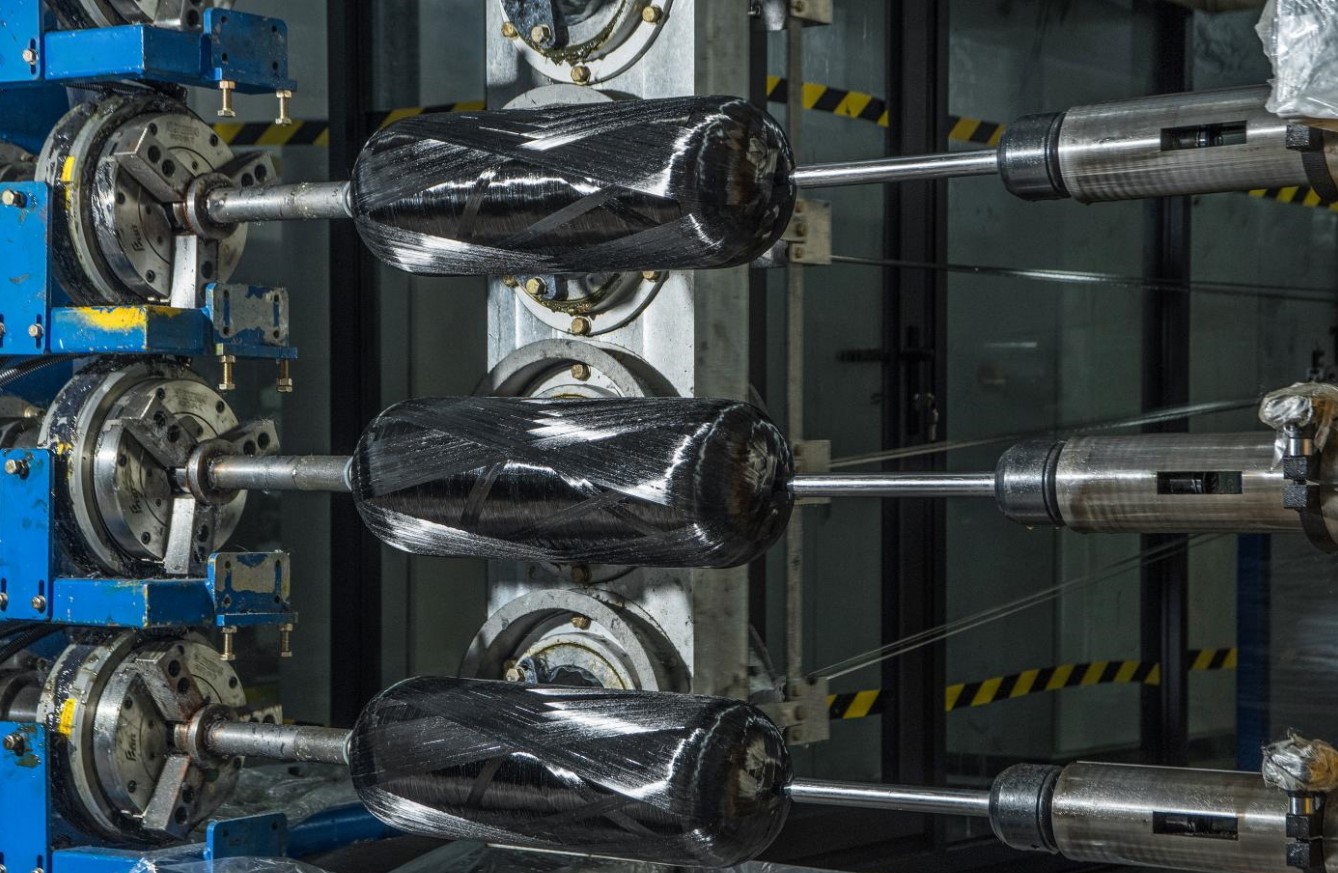

Idizayini Yomkhumbi Wokucindezela: Iklanyelwe Ukuphepha Nokuthembeka

Ukunikezwa komoya ngaphakathi kwemishini yokuphefumula kugcinwa kungcindezi ephezulu ukuze kuqinisekiswe ivolumu eyanele nokugeleza kogqokile. Lokhu kudinga umklamo oqinile wemikhumbi yokucindezela. I-Carbon fiber, enesilinganiso esiyingqayizivele samandla nesisindo, inikeza isisombululo esiphelele. Onjiniyela bangaklamai-carbon fibre cylinders ukuhlangabezana nezindinganiso zokuphepha eziqinile zokuvimbela ingcindezi kuyilapho ugcina isisindo sincane.

Nansi indlela ukuklama okucophelela okudlala ngayo indima ebalulekile:

-I-Fiber Orientation:Ngokuqondisa kahle amafayili ekhabhoni phakathi nenqubo yokukhiqiza, onjiniyela bangakwazi ukwandisa amandla esilinda ukuze bakwazi ukuphatha ukucindezela kwangaphakathi.

-Layup Techniques:Ukwendlaleka okukhethekile kanye nokuhlelwa kwemicu ngaphakathi kodonga lwesilinda kubalulekile ekuqinisekiseni amandla afanayo nokuvimbela amaphuzu abuthakathaka.

-Ukukhethwa kokubalulekile:Ukukhethwa kwe-matrix ye-resin esetshenziselwa ukubopha ama-carbon fibers nakho kudlala indima ekuphikisweni kwengcindezi kanye nokusebenza kukonke.

Lokhu kucatshangelwa kokuklama okucophelelayo kuqinisekisa lokhoi-carbon fibre cylinderImishini yokuphefumula ingaqukatha ngokuphephile ukuhlinzekwa komoya ocindezelwe, inikeze umsebenzi othembekile nosindisa ukuphila kumuntu owugqokile.

Ngalé kwamandla: Ukubhekana Nokumelana Nomthelela Ezimweni Ezingalindelekile

Nakuba i-carbon fiber idlula isilinganiso samandla nesisindo, ukumelana nomthelela kungenye into ebalulekile okufanele icatshangelwe endaweni enzima njengokucisha umlilo noma izilungiselelo zezimboni. Ukuqina okungokwemvelo kwezinhlanganisela ze-carbon fibre kungazenza zibe lula ekulimaleni ngenxa yemithelela ebuthuntu. Nokho, onjiniyela babhekana nale nselelo ngokusebenzisa:

-Strategic Fiber Orientation:Ukuhlelwa kwefayibha ethile kungathuthukisa ikhono lesilinda lokumunca amandla omthelela futhi lisabalalise ngempumelelo.

- Isistimu ye-resin eqinile:Ama-resin aklanyelwe ukuqina okuthuthukisiwe angathuthukisa ukumelana kwenhlanganisela ekulimaleni okuvela emithelela.

-Imiklamo yeHybrid:Ukuhlanganisa i-carbon fiber nezinye izinto ezimelana nomthelela njenge-Kevlar kungakha isilinda esinikeza amandla aphakeme nokumelana nezingozi noma iziteleka zemfucumfucu phakathi nezimo eziphuthumayo.

Lezi ntuthuko ziqinisekisa lokhoi-carbon fibre cylinderawasindi nje kuphela futhi aqinile kodwa futhi ayakwazi ukumelana nobunzima bokusetshenziswa komhlaba wangempela ezindaweni ezinzima.

Ukutholwa Nezicelo: Ukuphefumula Kalula Nge-Carbon Fiber

Izinzuzo zei-carbon fibre cylinderziholela ekwandeni kwazo zonke izinto zokuphefumula emikhakheni eyahlukene:

-Ukucima umlilo:Njengoba kushiwo ngaphambili, ukunciphisa isisindo kanye nokuhamba okuthuthukisiwe okuhlinzekwa yii-carbon fibre cylinders zibalulekile kubacimi bomlilo.

-Ukuphepha Kwezimboni:Abasebenzi abasebenza ezindaweni eziyingozi njengezindawo ezivalekile noma izitshalo zamakhemikhali bayazuza ezintweni ezilula kanye nezici zokuphepha ezithuthukisiwei-carbon fibre cylinders.

-Impendulo Ephuthumayo:Abaphenduli bokuqala kanye nabasebenzi bezokwelapha abasebenzisa amathuluzi okuphefumula phakathi nemisebenzi yokuhlenga noma izimo eziphuthumayo zezokwelapha bathola ukunethezeka okukhulu nokuhamba okuthuthukisiwe ngokukhanya.i-carbon fibre cylinders.

Ikusasa Liphefumula Kalula: Ukuqamba Okusha Okuqhubekayo Kokuklama Nobunjiniyela

Ukuthuthukiswa kwei-carbon fibre cylinderukuklama nobunjiniyela bemishini yokuphefumula kuwumsebenzi oqhubekayo. Abacwaningi bahlola izindawo ezimbalwa ezithembisayo zokuthuthukisa okwengeziwe:

- Ukuhlanganiswa Kwe-Nanotechnology:Ukufaka ama-nanomaterials ku-matrix eyinhlanganisela kungase kuthuthukise amandla futhi kube nomthelela wokumelana nakakhulu.

- Ukuhlanganiswa kwenzwa:Izinzwa zokushumeka

Isikhathi sokuthumela: Apr-30-2024